Understanding nylon totes is crucial for businesses aiming to meet modern consumer needs. Nylon tote bags have evolved significantly since their inception in the 1930s, combining durability with style. This article dives into the historical development of nylon totes, focusing on the material science that makes these bags robust yet lightweight. We’ll explore how premium brands utilize nylon for fashion and recognition, and compare the durability of nylon versus canvas totes. Furthermore, we’ll address the environmental implications of nylon tote production, ensuring that businesses can make informed choices that resonate with eco-conscious consumers. Each chapter builds on the previous one to provide a comprehensive view of nylon totes and their relevance to contemporary business strategies.

From Silk Substitute to Everyday Essential: The Historical Arc of Nylon Totes

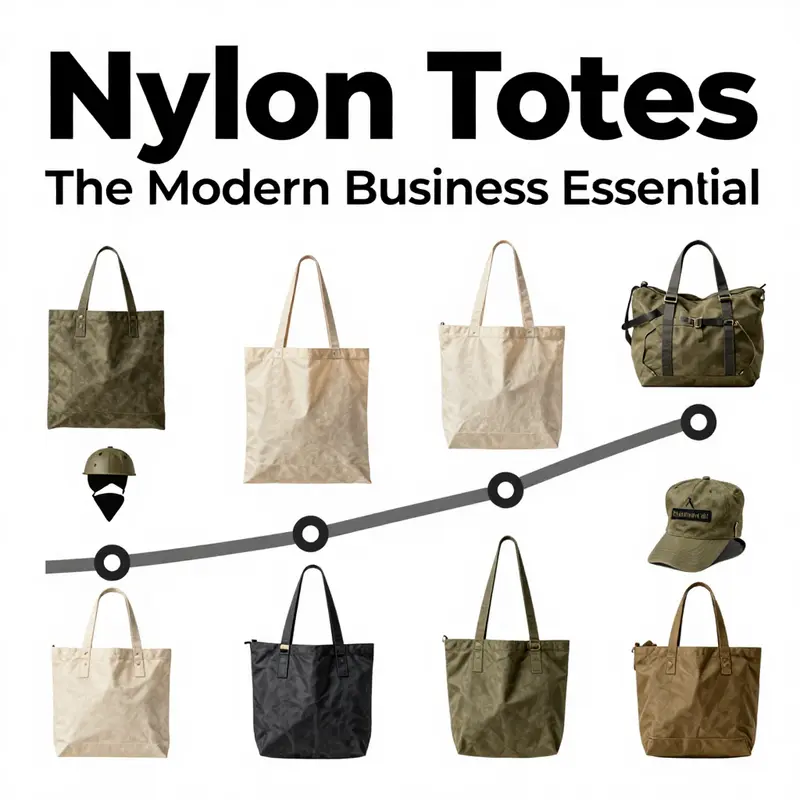

The history of nylon tote bags unfolds as a quiet, relentless arc that curves from laboratory ingenuity to the daily routines of millions. It is a story not merely of a fabric but of an idea—an idea that durability can be light, that water resistance can coexist with portability, and that a bag can be both workhorse and companion. To trace this path is to watch how a material born for silk’s substitute role in the 1930s quietly morphs into an everyday essential that travels from the sidewalks of cities to the back of buses, train stations, and airport lounges. The journey begins with a breakthrough in polymer science, where American chemists at a prominent chemical company conceived nylon as a synthetic treasure aimed at giving silk-like properties a modern, scalable alternative. Nylon offered strength, elasticity, and resilience that silk could not easily match in mass production. Those early laboratories imprinted a future on fabric—one where fibers could be spun thin, dyed evenly, and woven into fabrics that would resist wear, while staying light enough to reduce fatigue. The very idea of a tote bag—an implement to carry goods through daily life—found new expression once nylon demonstrated it could bear weight without the bulk and moisture-prone drawbacks of older textiles. In a broader sense, nylon’s ascent was not about replacing one material with another, but about expanding what a bag could do when designed with a different set of properties in mind. The tote, as a concept, benefited from that expansion. It needed to be flexible enough to hold groceries, books, or personal items; it needed to be durable enough to last through repeated use; and it needed to be water resistant enough to shrug off sudden rain or damp conditions that urban life routinely throws at travelers. Nylon, with its natural quick-drying quality and resilience, became a natural ally in this mission. The early days were more trial than triumph, and the market for nylon bags grew slowly as producers learned to balance texture, weight, and tensile strength with cost and aesthetics. Yet the material’s promise became increasingly evident as manufacturers experimented with different deniers, weaves, and finishes. The tote bag emerged not as a single perfect product but as a family of configurations: some with simple, pared-down silhouettes favoring lightness; others with reinforced panels and gussets designed to protect contents and withstand daily abrasions. The post-war era then accelerated nylon’s migration from specialized applications to consumer goods. World War II redirected nylon production toward parachutes, ropes, and various military equipment. The enormous scale of that production did not suppress consumer interest; it amplified it. After the war, nylon found new life in luggage and outdoor gear, then in shopping bags, and finally in the urban tote. The timeline is not a straight line but a series of convergences where utility meets design. The modern nylon tote owes much to this reconfiguration: a fabric once optimized for strength and endurance began to be refined for fashion, comfort, and practicality. The shift was not simply about using a tougher material; it was about rethinking how gaps in durability and moisture resistance could be closed through weaving techniques and coatings. Ripstop weaving played a crucial role in this transformation. The crosshatch pattern, which helps prevent tears from expanding, turned a potential weak point into a deliberate design feature. It allowed bags to flex with the wearer’s movements without compromising the integrity of the material, a quality that matters when a tote is loaded with books, groceries, a laptop, or gym gear. Alongside ripstop, coatings and hardware began to define nylon totes more clearly. Polyurethane coatings imparted water resistance without adding excessive weight, while reinforced stitching and rugged hardware ensured that handles, zippers, and metal accents could withstand repeated use. The interplay of these choices—weave, coating, stitch, and hardware—became the language through which manufacturers translated nylon’s inherent strengths into real-world performance. As the decades progressed, the market moved toward varieties labeled by denier ratings, a metric that correlates with the density of the fiber and, by extension, its potential for load-bearing and abrasion resistance. Today’s practical ranges sit in the mid-denier spectrum—roughly from 420D to 600D for mainstream totes—while higher-end options lean into even denser constructions. The conversation, however, is not merely about numbers. It is about how those numbers translate into everyday reliability. A well-constructed 420D bag, when designed with careful seam work and thoughtful layouts, can outlast a poorly designed 1000D model. That observation underscores a key thread in the nylon tote narrative: smart design can trump sheer thickness. The material matters, but the way it is cut, stitched, and finished matters more. And that is why the modern nylon tote balances both form and function with surprising grace. It is a testament to how far textile engineering has come since the material’s early uses in hosiery and parachutes. Contemporary totes often incorporate strategic features that speak to today’s lived realities: padded compartments for a laptop or tablet, internal zippered pockets for valuables, weather-resistant linings, and discreet, reinforced corners that resist abrasion from repeated placement on city sidewalks and luggage carousels. The design ethos remains pragmatic, yet it has grown more sophisticated as consumers demand versatility in a single bag. The environmental impetus behind nylon totes has also matured. Reusability has become a moral as well as a practical decision, spurred by the realization that replacing cheap, disposable plastic bags repeatedly is neither economical nor ecologically responsible. Nylon’s durability makes it a rational choice for those who want a single bag to serve across several contexts—commuting, weekend getaways, and errands—without the constant need to replace it. In this light, nylon totes align with a broader shift toward sustainable, long-lasting goods that reduce waste while offering dependable performance in diverse weather and urban settings. The material’s water resistance and mildew resistance add another practical layer. Moisture in urban environments, a common annoyance, can compromise contents and hasten decay in less robust fabrics. Nylon’s resistance to moisture keeps electronics, papers, and clothing drier, while its breathability helps manage heat and humidity that accumulate when a bag is carried all day. The appeal is not solely functional; it is also stylistic. Nylon’s sheen, its ability to hold bold colors, and its capacity to maintain a sleek silhouette even when filled contribute to a versatile aesthetic. Designers have embraced nylon totes as a means to achieve a modern, utilitarian look that still communicates polish, making them a suitable companion for both office corridors and travel hubs. The evolution of nylon totes also mirrors a broader consciousness about material choice and consumer behavior. As shoppers develop an eye for value—where long-term cost, wear, and repairability matter as much as initial price—they increasingly seek products that offer a favorable balance of durability, water resistance, and ease of maintenance. The tactile feel of nylon, its resistance to scuffs and abrasion, and its ability to shed light rain without swelling or warping create a timeless utility that resonates with daily life. In this sense, the historical arc of nylon totes is less about a single revolutionary moment and more about a sequence of improvements that collectively redefine what a bag can endure. The field has matured into a space where robust materials and refined construction coexist with contemporary design sensibilities. The result is not only a bag that can withstand the rigors of an unpredictable day but one that remains comfortable and adaptable as it travels from a crowded subway platform to a quiet office, or from a weekend market to a formal event. For readers who want a tactile sense of how the evolution translates into practice, consider the idea of a tote bag with computer sleeve as an exemplar of how nylon’s durability meets modern digital needs. This kind of configuration demonstrates how the material’s properties support a protective, structured layout without compromising portability or lightness. It epitomizes the marriage of utility and design that has become the hallmark of nylon totes. As the industry continues to refine fibers, we may see even smarter weaves, more sustainable coatings, and hardware that optimizes weight while increasing resilience. Yet the core insight remains simple: nylon’s journey from a silk substitute to a mainstay of daily life is rooted in a steady emphasis on durability, moisture management, and thoughtful design. The tote, once a humble carrier, has become a platform for ongoing innovation—an emblem of how fabric science shapes the everyday objects that accompany us through work, travel, and recreation. External references and ongoing research reinforce the idea that material choice matters, not only for performance but for its compatibility with evolving lifestyles. For readers who wish to explore broader perspectives on durability and sustainability in nylon bags, see the external resource linked below. External resource: https://www.researchgate.net/publication/398745678UnderstandingtheRiseofNylonBagsAModernSolutiontoDurabilityand_Sustainability. And for those curious about linked product examples and design ecosystems, consider examining the concept of a digitally aware bag that retains structure with a computer sleeve, which can be explored here: tote bag with computer sleeve.

Weaving Strength: The Molecular Science Behind Durable Nylon Totes

Nylon tote bags sit at the intersection of science and everyday practicality. They were born in the 1930s as a silk substitute and were quickly refined for demanding tasks like parachuting and military gear. The story behind their success is not merely about synthetic material; it is about how a carefully engineered polymer system translates into a bag that remains light, flexible, and remarkably tough from dawn to dusk. The essence of nylon’s durability lies in its molecular architecture. Polyamide chains are tightly packed and aligned in ways that create a fabric with high tensile strength, excellent abrasion resistance, and a natural resilience to stretching. This is not just about raw strength; it is about controlled energy transfer. When force is applied, the polymer chains slide and realign rather than snap, distributing stress across the weave and preventing sudden seam failure. That subtle choreography at the molecular level makes nylon totes capable of carrying heavier loads without surrendering to wear, which is a reality for commuters, students, and travelers who rely on one bag day after day.

A critical feature of many nylon totes today is the ripstop weave. The fabric’s distinctive crosshatch reinforcement works like a network of tiny safety nets. Small tears that develop under stress are less likely to radiate into larger rips, allowing the bag to maintain its shape and integrity even when subjected to rough handling or accidental snags. This structural strategy is paired with finishes designed to fight moisture and spills. A durable water repellent, or DWR, is often applied to keep surface water from saturating the fibers, so a sudden rain shower or a splash from a commuter train platform won’t drench the contents. The combination of ripstop geometry and water-repellent treatment is a practical synthesis of form and function, offering a practical shield against city life’s unpredictable weather and daily friction.

The hydrophobic nature of nylon contributes to another essential advantage: quick drying. Unlike natural fibers that soak up moisture and stay damp, nylon resists water absorption. Water beads up and rolls off the surface, which translates into faster drying times and less chance for mildew when a bag is stored in damp conditions between uses. This hydrophobic property also means that nylon bags remain relatively light even when lightly wet, an important consideration for travelers lugging bags through rain-soaked streets or into crowded transit hubs. Yet this very strength has its caveats. Ultraviolet light from the sun can slowly degrade nylon fibers through photodegradation. Prolonged exposure can make the fabric brittle and less resistant to tearing. To counter this, many manufacturers incorporate UV stabilizers during production, a deliberate addition that slows chain scission and helps preserve color and strength over years of exposure. The result is a fabric that not only resists the wet and the rough but also stands up to the sun’s long reach when a tote is left on a balcony, car seat, or rooftop porch.

Moisture management, strength, and lightness come together with a critical measure of performance: how a fabric holds up under abrasion. Industry testing has shown that nylon can retain a significant portion of its tensile strength after repeated rubbing and friction. In standardized studies, nylon fabrics can retain over 90 percent of their original tensile strength after hundreds of abrasion cycles, far surpassing say, standard cotton canvas in similar tests. This resilience translates into real-world durability: a tote that maintains its seam integrity when hauled through subway gates, loaded with groceries, or stuffed with textbooks and a laptop. The practical implication is not simply about resisting tearing; it is about sustaining load-bearing capacity under everyday stresses, which is precisely what makes nylon especially suitable for daily wear in urban environments and beyond.

Another quantitative benchmark often cited in material specifications is the denier rating, which describes the fiber thickness. A 1000D nylon, for example, offers substantial strength for its weight, able to withstand substantial direct pull before seam failure. This level of performance helps explain why premium and performance-oriented totes lean toward high-density nylon fabrics. When these bags are designed with reinforced seams, double-stitched hems, and well-considered hardware, the material’s inherent strength has room to shine without excess bulk. The balance between weight, durability, and price becomes a central design question, and manufacturers navigate it by choosing the appropriate nylon density for the intended use—whether a light day bag for city commuting or a robust travel tote meant to carry laptops, books, and all the gear of a busy life.

Of course, aesthetic considerations must align with these material advantages. Nylon’s smooth surface and the way it takes dye can yield a modern, understated look that fits both urban fashion and travel gear. The fabric’s resistance to moisture means finishes and trims can be chosen with less concern about water damage during routine use. In premium fashion and travel accessories, designers often pair nylon with leather accents, metal hardware, and structured silhouettes to achieve a look that communicates practicality without sacrificing style. Brands approach nylon as a versatile canvas: it can be crisp and architectural for a city silhouette, or softened and pliable for relaxed, everyday carry. Even as nylon evolves to meet contemporary expectations, its core attributes—strength, water resistance, and light weight—remain its defining advantages for tote design.

For those who need a practical, tech-friendly carry, the design logic often centers on safeguarding the contents without sacrificing ease. A built-in laptop sleeve or compartment is a common feature in modern nylon totes. For the urban commuter who carries tech, a nylon tote with a built-in laptop sleeve tote bag with computer sleeve offers both protection and lightness. The sleeve is typically padded and aligned with a snug fit to prevent movement, while the surrounding fabric remains flexible enough to reduce bulk. The material’s tensile strength supports a confident load around sensitive devices, and the overall weight of the bag remains manageable enough to shoulder comfortably through long days.

But a durable bag must endure more than just one season. The long-term performance of nylon totes hinges on how they are cared for and how their finishes age. Routine care—gentle cleaning, avoiding harsh solvents, and allowing the bag to dry completely after exposure to rain—helps preserve both the fabric and the DWR coating. Over time, some wear may appear as slight fading in color or micro-scratches on the surface. These changes are typically superficial and do not compromise core performance, especially if the bag has been designed with reinforced stress points and high-quality stitching. The best nylon totes are built with a philosophy of longevity: materials and construction that resist the three common modes of degradation—moisture intrusion, tearing, and surface abrasion—while maintaining a usable form and flexible, reliable function.

User experience is also a function of how the bag’s geometry and fabric interact in real life. The body of the tote may be designed to balance capacity with compactness, allowing a roomy interior without creating a shoulder-dragging silhouette. The fabric’s natural resilience helps the bag rebound from compressive loads, so it does not crumble when stuffed full. Ripstop panels or panels arranged with strategic reinforcement in high-stress zones add a level of durability that translates into consistent form over time. In this sense, nylon tote construction reflects a holistic approach: a marriage of polymer science, fabric engineering, and thoughtful design that recognizes how people carry their daily lives from sunrise to sunset.

The science of nylon is not a solitary pursuit; it informs decisions across every stage of product development. Material selection governs weight, water resistance, and load-bearing capacity; weaving patterns determine tear propagation and abrasion resistance; coatings and stabilizers extend life under sun and rain. The end product is a bag that behaves predictably under a spectrum of conditions—humid commutes, crowded trains, or weekend getaways—while maintaining an aura of understated practicality. The journey from polymer synthesis to a ready-for-use tote demonstrates how a material once developed for parachutes and military gear has become a cornerstone of everyday carry, proving that durability can be elegant, lightweight, and dependable all at once.

External resource for further reading on fabric durability standards: https://www.aatcc.org/standards/

Nylon Totes as a Language of Fashion: Durability, Design, and Brand Identity

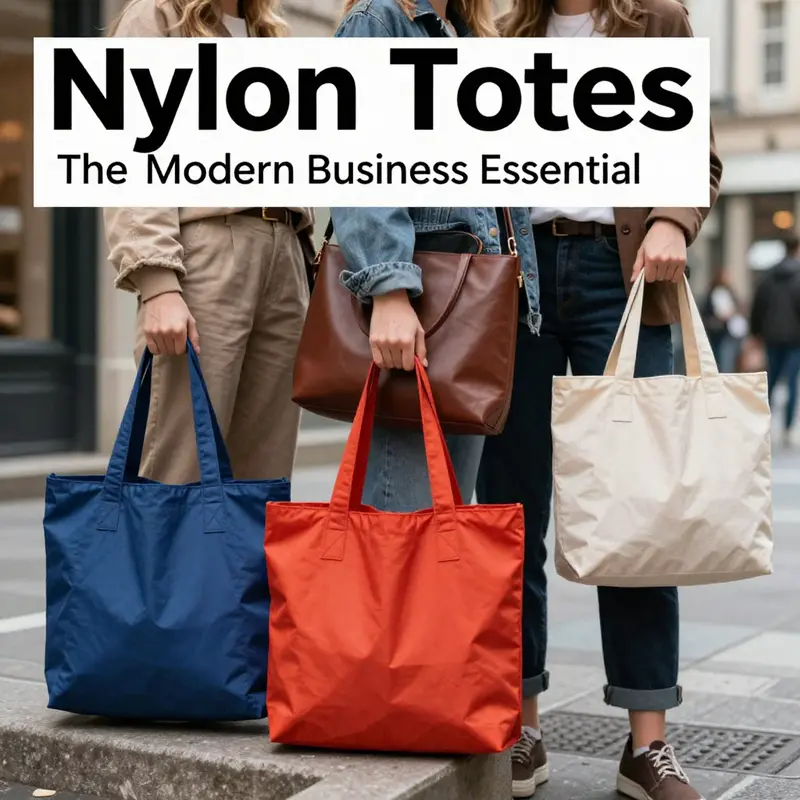

Nylon tote bags have traveled a long arc from utilitarian carryalls to coveted fashion statements. Their evolution is not just about a material upgrade but about a shift in how we read everyday objects. A nylon tote is at once a practical tool and a canvas for personal style, capable of keeping pace with urban rhythms, weekend escapes, and office routines without demanding compromise. The fabric’s core strengths, durability, lightness, and water resistance, are what make nylon totes reliable companions in weather that shifts from misty mornings to sudden showers. High-density variants, including ballistic nylon and tough ripstop weaves, reinforce that reliability. In a world where bags are tested by daily commutes, gym sessions, and hurried errands, nylon totes offer a superior balance of strength and ease that sits comfortably with modern wardrobes. They resist wear, maintain their shape, and can endure the rigors of day after day use, a natural draw for anyone who wants form to follow function without feeling constrained by gear-like aesthetics.

What distinguishes nylon totes in the current fashion landscape is less a single, loud statement and more a quiet confidence. The material reads as contemporary, a shade of practicality that pairs well with minimalist silhouettes, refined hardware, and carefully considered color palettes. The result is a bag that feels intentional rather than utilitarian, a reminder that durability can coexist with elegance. Designers have embraced this possibility by shaping nylon into structured, balanced forms that project polish even when the tote is unembellished. The visual language is understated but unmistakable: clean lines, precise stitching, and a surface that catches light with a matte sophistication or a subtle sheen, depending on weave and finish. Ripstop weaving, for instance, introduces a lightweight grid that adds texture and resilience without shouting for attention. The effect is modern credibility—an accessory that conveys competence and poise in equal measure.

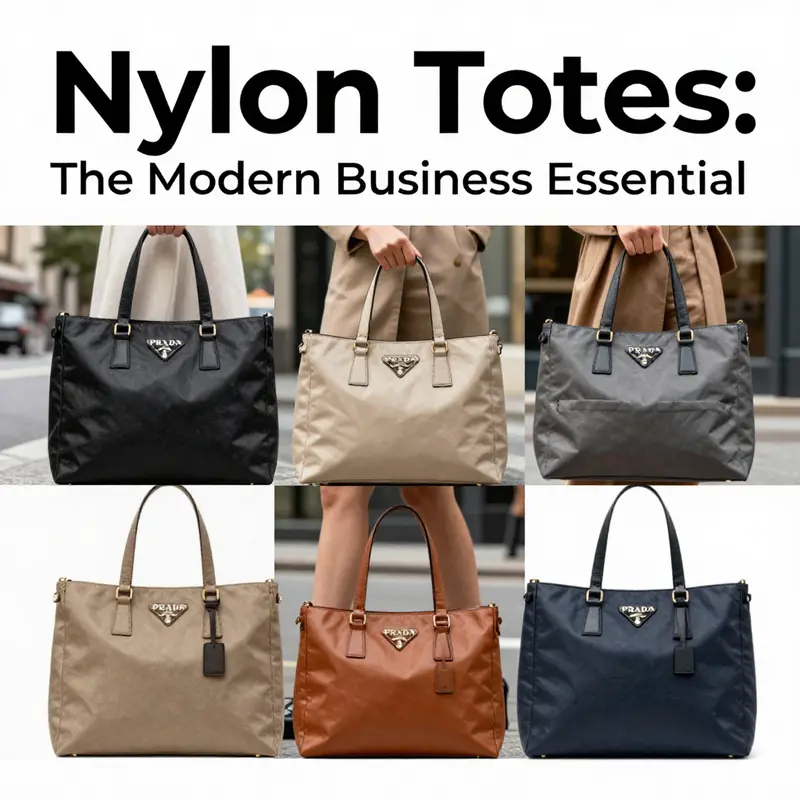

Brand perception has been a crucial driver of nylon totes becoming fashion fixtures. When durability is paired with aesthetic clarity, the bag becomes less a disposable carrier and more a durable companion that earns its spot in the daily ensemble. Brands that master this balance do more than vend a product; they tell a story about longevity, design integrity, and everyday value. The core message is simple: a bag should endure a quarter of daily use or more and still feel relevant across seasons. This philosophy translates into real design decisions—reinforced seams, robust strap attachments, and weather-ready finishes that resist staining and fading. The practical advantages become signals of quality without depending on loud branding. In this way, nylon totes contribute to brand equity by aligning performance with a refined sensibility. They become reliable touchpoints in a crowded market, where the first impression often comes from how a bag behaves under pressure.

The visual credibility of nylon totes extends beyond performance and into the language of contemporary fashion. A well-executed nylon tote communicates seriousness through its form. Minimalist silhouettes—structured with a calm, architectural balance—allow the material to speak for itself. The absence of overt logos can paradoxically increase a bag’s status, because the emphasis shifts to the tactile and visual cues: the tactility of the fabric, the weight and texture of hardware, the precision of stitching, and the way the bag holds its shape when filled. In this sense, the tote becomes a wearable emblem of modern craft. Celebrities and influencers in major fashion capitals often showcase this ethos by pairing a clean nylon silhouette with smart casual or tailored office wear. The result is a cross-cultural appeal that travels well across Asia, Europe, and North America, turning a practical carry into a versatile style instrument. The bag is equally at home on a crowded subway, in a hotel lobby, or at a weekend gallery opening, which only strengthens its cultural resonance.

Material science plays a quiet but decisive role in shaping consumer expectations. The choice of nylon—when paired with a robust weave, reinforced seams, and thoughtful finishing—creates a sense of predictability that many shoppers value. Moisture resistance means a bag can dry quickly after rain, while abrasion resistance preserves the surface against daily contact with rough edges and hardware. The result is a tote that does not demand special care beyond routine upkeep, a quality that resonates with buyers seeking long-term value. In a market where fashion often oscillates between fleeting trends and timeless utility, the longevity of nylon totes is a persuasive argument for their continued relevance. A bag that keeps its shape, color, and tactile integrity after repeated fills and washes speaks to a design philosophy that prioritizes enduring performance.

The sustainability narrative around nylon totes intersects with consumer desires for durable, low-maintenance products. Far from being a disposable commodity, a well-made nylon tote invites stewardship: it invites owners to invest in a single piece that can accompany them through multiple chapters of life—commutes, travel, family activities, and spontaneous weekend explorations. The ease of care—many nylon totes can be wiped clean or even machine washed without losing form or color—enhances their value proposition. This practicality aligns with a broader shift in fashion toward products that endure both wear and time, reducing the need for frequent replacements. As a material, nylon’s resilience under moisture and UV exposure helps it resist the kind of environmental wear that threatens other fabrics. The upshot is a bag that ages gracefully, gaining a story-filled patina rather than showing the scars of neglect.

From a brand perspective, the nylon tote has become a flexible canvas for storytelling. It can communicate urban professionalism on weekdays and relaxed readiness for weekend escapes without requiring a wardrobe overhaul. The tote’s design language—structured proportions, measured hardware, and restrained colorways—supports a versatile, cross-season presence. In this sense, nylon tote design serves as a barometer for how fashion values durability and practicality as components of luxury. The material becomes a conduit for a modern aesthetic that refuses to sacrifice function for form. It signals a shopper’s intent to invest in a piece that will perform day after day, season after season, and across a diverse range of activities. The result is not merely a bag but a functional emblem of a lifestyle that prizes efficiency, reliability, and understated elegance.

For readers seeking a sense of how these design cues translate into everyday shopping guidance, consider how the concept of a durable, stylish tote can be conveyed through accessible product summaries and curated visuals. A practical example is the way tote silhouettes are framed in contemporary retail storytelling: a clean, unembellished profile, a carefully chosen palette, and hardware that reads as both sturdy and refined. Such narratives help consumers understand that quality is less about brand labels and more about bold, simple lines that endure. The nylon tote, then, becomes both a tool and a statement—a practical ally that communicates competence, taste, and a readiness for whatever the day might bring. This alignment between material capability and stylistic clarity is what keeps nylon totes salient in a crowded market and ensures they continue to evolve without losing their essential identity.

As a practical takeaway, shoppers can look for a tote with a few nonnegotiables: a strong, well-constructed base; reinforced stitching at stress points; a dependable zipper or closure; and a fabric that feels sturdy yet flexible. The result is a bag that not only carries the essentials smoothly but also ages with confidence, remaining visually coherent as it accumulates memories. The beauty of nylon lies in its honesty: it earns respect through what it can endure and how gracefully it wears. In a landscape where fashion often leans toward the transient, a nylon tote stands out by offering a dependable, adaptable, and unmistakably modern option that a broad range of buyers can make their own. For a tangible glimpse into how silhouette and material language translate into real-world carry options, consider how the tote coach handbags page frames durable nylon totes.

External resource for further reading on durability and style in nylon totes: https://www.britishstyleguide.com/guides/durable-nylon-tote-bags/

Weighing Strength and Style: A Deep Dive into Nylon Totes Versus Canvas Totes for Everyday Use

A tote is more than a simple carrier; it is a compact commitment to how we move through our days. When the choice comes down to nylon versus canvas, durability becomes a practical measure that intertwines with weather, routine, and the way we pack. Nylon totes stand out for their lightness and their ready resistance to the elements, while canvas totes are prized for a rugged, timeless feel and a patience with wear that many find reassuring. The question isn’t which fabric is better in an abstract sense, but which one aligns with the demands of daily life and the small, repeated stresses that shape a bag over months and years. In this light, durability emerges as a composite quality—how the material behaves under load, how it handles moisture, how it resists abrasion and sun, and how it endures the cycles of use and washing that every tote must survive.

Nylon is celebrated in technical textile circles for its strength-to-weight ratio. In the realm of tote construction, a common reference point is a high-density nylon, often described as 1000D, which signals a fabric heavy enough to carry substantial loads while still remaining relatively light on the shoulder. The notion of endurance for nylon is multifaceted: in some direct-pull tests, these fabrics can tolerate more than sixty pounds before a seam shows strain, and in other controlled evaluations, the numbers climb well past one hundred pounds before failure. That range reflects the diversity of manufacturing methods, weaving patterns, and seam construction. The reality for everyday users, however, tends to settle around a practical truth: nylon totes can carry heavier loads with less visible shapeshifting compared to many other fabrics, a quality that makes them especially reliable for groceries, work gear, or gym setups that come with extra items and occasional spills. The lighter weight means you can stuff more without the bag itself turning into a burden, and the fabric’s inherent elasticity helps absorb shocks that might otherwise stress the seams in a heavier natural textile.

A key feature that consistently tilts the balance toward nylon is moisture management. Nylon resists water absorption far more than canvas. Light rain or mist beads gather on the surface and roll away rather than soaking in, and many nylon totes come with a durable water repellent, or DWR, coating that adds an extra layer of protection against damp days, splashes, or accidental spills. This moisture resistance translates into practical advantages: things inside stay drier, handles don’t soak through with a sudden shower, and the overall weight of the bag remains manageable even when conditions are damp. By contrast, canvas—often cotton-based—acts like a sponge when it encounters moisture. The fabric swells as it absorbs water, and that swelling can put additional strain on stitching points and seams during or after heavy use, especially when carried by hand or on one shoulder for extended periods. It’s not a fatal flaw, but it is a factor that encourages more deliberate care in wet weather and a recognition that the bag’s behavior changes with the environment.

The durability story for canvas centers on structure and texture. A tightly woven, thick canvas tote has an almost comforting rigidity that reduces the likelihood of snagging and tearing under moderate loads. The material’s natural breathability can be a benefit in some climates, and its surface tends to show wear in a way that many find aesthetically pleasing. However, canvas is a natural material with inherent tendencies that nylon largely overcomes. When canvas gets wet, its fibers swell and the fabric becomes heavier, which can influence the way seams hold up under repeated stress. Carried on a daily basis, canvas often requires more attentive care to prevent long-term fabric fatigue, particularly around high-stress zones like handles and corners. Still, canvas has a washability advantage that nylon cannot always claim. In machine washing, canvas can withstand repeated cycles better than some nylon constructions, which makes it appealing to those who want a bag that looks good and cleans up in a home washer. The practical upshot is: canvas rewards careful maintenance with longevity in appearance and form, while nylon rewards ongoing performance with low maintenance needs and fewer burdens on care routines.

In terms of resilience against abrasion and puncture, the conversation becomes more technical but equally relevant to daily life. Modern nylon totes often employ ripstop weaving, a crosshatch pattern designed to arrest tears and keep small rips from propagating. This structural approach means that a minor snag is less likely to become a full tear, a feature that matters when a bag routinely brushes against countertops, car doors, or rougher urban fixtures. Abrasion resistance, when paired with the fabric’s elasticity, helps the bag recover from minor stretch without sagging or losing shape, which in turn preserves load distribution over time. Canvas, while robust in texture, loses some of that elasticity advantage. A stubborn snag can extend into a longer tear if the fabric is strained repeatedly, particularly when the bag is loaded heavily. Yet the canvas weave contributes to a sense of permanence; the bag looks and feels sturdy even after long use, and old-school durability has a charm that many users associate with reliability.

The calculus of UV exposure also plays a role in long-term performance. Nylon tends to resist cracking and rapid degradation under sunlight better than many natural fibers or faux leathers. In dry, sunny environments, nylon can maintain its integrity longer, with colors and fibers holding up under routine exposure. Canvas fares differently; while it can shrug off typical daily sun if designed with colorfast dyes, prolonged UV exposure can gradually fade or weaken fibers, particularly if the fabric is lighter-weight. The practical implication is subtle but real: nylon bags may preserve their appearance with less aggressive sun exposure, while canvas may demand a little more care if you live in a place where outdoor time is frequent and long.

Of course, durability is not solely about the material; it is about how the bag is built and how it is used. Seam quality, stitching patterns, and how a bag is loaded all shape its life. A well-constructed nylon tote with reinforced stitching at the handles, a durable bottom panel, and careful seam geometry can outlast a poorly made canvas bag under the same load because the nylon fabric resists tearing and resists moisture intrusion. Conversely, a robust canvas tote with double-stitched seams and a sturdy bottom can endure repeated loading with a certain timeless sturdiness, particularly if carried in a way that distributes weight across the body rather than concentrating effort at one weak point. In the practical routine of daily life—commuting, shopping, or travel—the difference often comes down to one’s weather patterns, washing habits, and the kinds of stresses the bag experiences week after week.

Another layer to consider is the long-term maintenance that each material demands. Canvas tends to respond well to careful washing, which means that a bag can be refreshed by following gentle washing procedures and air-drying away from direct heat. Nylon, especially when treated with a DWR, benefits from occasional refreshers of surface care—a wipe-down, the reapplication of protective coatings as wear dictates, and mindful storage away from sharp objects that could cause micro-tears. When you combine these care practices with a clear understanding of your typical environment—whether you’re navigating rainy commutes or dry city streets—the durability equation becomes clearer: nylon’s weather resilience and lighter weight reduce ongoing stress; canvas’s sturdiness and washability offer a more traditional, easily revived appearance. In each case, the bag’s construction matters as much as the fabric. A well-made nylon tote that fits your load profile will feel lighter and more forgiving during a week of heavy use, while a canvas tote with strong seams and a reinforced base will reward care with a long, steady performance that looks better with age.

For readers seeking a quick way to visualize these dynamics, consider the context in which you typically pack. If your days mix rain and dry spells, with frequent errands and transit and little time for intensive care routines, nylon becomes a sensible ally. The fabric’s moisture resistance and light weight reduce both the risk of damp contents and shoulder fatigue, making it easier to sustain a busy rhythm. If your lifestyle leans toward a more deliberate, aesthetic approach—occasional washing, a preference for a traditional, tactile feel—the canvas bag offers a timeless option that remains comfortable to carry even when loaded with everyday items. The choice, in short, aligns with priorities: weather resilience and ease of care on one side, a classic look and proven washing resilience on the other. Regardless of the path chosen, it is worth acknowledging that neither material is universally superior; each has a distinct durability signature shaped by density, weave, finish, and how the bag is used day after day.

To explore a related angle and broaden the sense of material choices in tote design, you can view canvas tote options among the broader collection of bags that emphasize practicality and style: canvas tote bags. This resource helps illuminate how canvas varies in weave, weight, and finish, which can influence durability under load and wash cycles. For those who want to dig deeper into the practicalities of care and performance, empirical testing and expert observations suggest a nuanced picture: nylon often offers superior endurance under mechanical stress and weather exposure, while canvas offers steadfast appearance and straightforward care in washing environments. The insight is not a simple winner-takes-all verdict, but a guide to match material properties with daily routines and weather realities.

In the end, the durability difference between nylon and canvas totes rests not only on the fabric itself but on how well the bag is designed to cope with real-world stress. A properly constructed nylon tote with thoughtful reinforcement can surpass expectations in the context of heavy daily use and unpredictable weather. A well-built canvas tote, meanwhile, can deliver enduring shape and a classic presence that withstands time with careful care. The best choice, then, is the one that aligns with your cadence: the tempo of your week, the weather you navigate, and the way you carry the world—with a bag that supports your life rather than demands constant adjustment. If you want to see practical examples of canvas options in the broader tote landscape, you can explore canvas tote bags as a reference point for texture, heft, and care strategies. canvas tote bags.

External resources and ongoing testing continue to refine our understanding of how these materials perform under real-life conditions. For a broader empirical perspective on laundry durability and wear under typical care conditions, see the LifeTips analysis of cotton canvas versus nylon tote laundry durability. This resource provides data points that help connect everyday care routines with long-term performance: https://www.lifetips.com/laundry-durability-test-cotton-canvas-vs-nylon-tote

Weaving Responsibility: Environmental Realities and Sustainability in Nylon Totes

Nylon totes often appear in everyday life as reliable companions for work, travel, and quick errands. They promise lightness, weather resistance, and the reassurance that a bag can endure busy urban routines without succumbing to wear. Yet the sustainability story behind nylon totes is not simply a tale of reuse and long life. It is a nuanced ledger that weighs the energy and materials required to produce them against the practical value they deliver through repeated use. To understand how a nylon tote fits into a responsible wardrobe, one must trace the chain from raw material to end of life, and then evaluate how those scales balance in real-world use. In that sense, the ecological footprint of a tote hinges not just on how long it lasts, but on how its lifecycle interacts with climate pressures, waste streams, and the behaviors of the people who carry it.

The production of nylon begins with crude oil, a fossil feedstock whose conversion into polymer creates energy-intensive processing and emissions. Among the greenhouse gases associated with nylon manufacture, certain nitrogen oxide compounds stand out for their climate impact. Nitrous oxide, for example, carries a global warming potential far greater than carbon dioxide over a century-long horizon. When that gas is released in the course of making nylon, the initial phase of a tote’s life can contribute disproportionately to climate impact, particularly if the product is valued mainly for its longevity rather than its reuse. The point is not to demonize nylon but to acknowledge that sustainability is a system property, not a single attribute. The same durability that makes nylon attractive also anchors the conversation in lifecycle thinking: a bag must be used many times to offset the environmental costs embedded in its creation.

Durability itself is a defining feature that often tilts the sustainability balance in nylon’s favor. High-denier variants are designed to resist tears, abrasion, and the rigors of daily handling. In controlled testing environments, nylon with denier levels from 420D up to 1000D can retain substantial strength even after hundreds of cycles of wear. For instance, high-denier nylon can maintain more than 90 percent of its tensile strength after roughly five hundred abrasion cycles, a performance far exceeding that of many natural fibers commonly used in bags. This resilience translates into longer service life, reduced frequency of replacement, and, by extension, less waste churn over time. The tradeoff is not simply material endurance; it is how that endurance interacts with the unpredictable rhythms of daily use, from heavy rain to crowded commutes, and how well the bag can be repaired or rehabilitated when it shows signs of aging. In the end, durability becomes a form of value if it is paired with responsible care and thoughtful design choices.

Another essential aspect of the sustainability dialogue is the end of life for nylon products. Nylon is inherently resistant to moisture and dries quickly, but these same properties contribute to environmental persistence. Unlike many natural fibers, nylon does not readily biodegrade in landfills or in environmental settings. Instead, it fragments into microplastics that can persist for long periods, potentially entering waterways and ecosystems long after the tote ceases to be useful to a wearer. The lack of easy end-of-life solutions complicates the sustainability case. Recycling nylon, while technically feasible, faces material and logistical hurdles — from contamination and dye residues to the economics of recycling streams that may not be optimized for post-consumer nylon bags. In practice, these challenges mean that a nylon tote’s green premium depends not only on its reuse but also on how society can manage the bag at the end of its life, a question that remains less settled than the promise of durability it provides.

Within this framework, the conversation about nylon’s environmental footprint often returns to a core paradox: durability supports longevity, yet the production path carries heavy climate and persistence costs. The American Association of Textile Chemists and Colorists, among other textile researchers, notes that the durability of nylon is real and measurable, with performance metrics that underscore why the material is favored for demanding use. The pressing question for consumers and designers alike is how to translate that durability into a diminished ecological footprint. If a tote is used every day for several years, the cumulative environmental impact of its production can be spread over a larger base of use, making the reuse argument stronger. But if the bag is discarded prematurely or disposed of in ways that fail to capture end-of-life opportunities, those early-stage emissions loom larger in the overall picture. It is a nuanced calculus: use patterns, maintenance rituals, and the capacity to recover value at the end of life all shape whether nylon remains a prudent choice.

That calculus also invites consideration of alternative materials and ways to rethink bag design. For some applications, recycled polyester or plant-based fabrics may offer lower lifecycle emissions and a different end-of-life trajectory. Each material carries its own set of trade-offs, which means that the most sustainable option depends on context, including how often the bag is used, how it is cared for, and how a consumer disposes of it at the end of its life. The goal is not to prescribe a single path but to illuminate the decisions that people can influence. In practice, this means looking for signs of thoughtful engineering that extend life without sacrificing performance. Ripstop weaving patterns, reinforced crosshatch structures, and high-quality seams, for instance, can help prevent tear propagation and delay replacement, thereby maximizing the use cycle between repairs. These features, while technically focused, have a larger implication: each design choice that reduces premature failure contributes to a more responsible lifecycle.

The materials story behind nylon totes also intersects with broader conversations about fashion and consumption. The market has shown a demand for durable, low-maintenance bags that perform across weather conditions and daily routines. This demand aligns with sustainability goals when it translates into reduced reliance on single-use alternatives and fewer bags discarded after brief use. Yet the same demand can pressure manufacturers to emphasize abrasion resistance and water repellence over reparability or end-of-life options. The tension between rugged performance and recyclability is not unique to nylon; it is a common thread in modern fabric design. The best outcomes arise when designers adopt a life-centered approach that values repairability, modular components, and clarity about recycling pathways. Such an approach helps ensure that the durability of nylon becomes a resource for longevity rather than a barrier to end-of-life recovery.

Consumer behavior plays a crucial role in shaping nylon totes’ sustainability profile. A bag that travels with a user to work, the gym, and weekend trips for many years can amass a smaller per-use environmental cost than a bag that is replaced after short terms of use. That reality, however, depends on care routines that respect the fabric’s needs. Gentle washing, avoidance of harsh solvents, and prompt repair of small tears can extend the life of a tote without triggering disproportionate environmental costs. Conversely, neglect or improper disposal can undermine the advantages of durability. The value proposition of nylon lies not in a single attribute but in how the material is managed across its life. Consumers who understand this are more likely to weigh total lifecycle impact when choosing a bag and to seek products designed with repair and recycling in mind.

For readers tracking the evolving landscape of tote design, trends matter as much as material science. The broader market shows growing attention to durability, adaptability, and responsible production practices, all of which feed into a more sustainable narrative for bags that perform across seasons and climates. If you want to explore how trends in tote design intersect with sustainability, see the ongoing conversation around tote-bags-trending. This touchpoint helps connect the practical realities of fabric choice with the cultural shifts that influence what people expect from a carryall in daily life, particularly regarding longevity and repairability.

Careful assessment of nylon’s lifecycle invites a pragmatic stance: nylon totes can be a sustainable option when chosen with attention to production ethics, producer transparency, repairability, and end-of-life pathways. The field remains a work in progress, with researchers urging more robust system-level solutions for recycling post-consumer nylon and reducing the climate costs of production. In the meantime, consumers can contribute by selecting totes with clear recycled content, supporting repair-friendly constructions, and maintaining the bag to maximize its lifespan. Such steps do not erase the environmental costs embedded in nylon production, but they do shift the balance toward a more purposeful consumption pattern that recognizes the real costs and benefits of a durable bag.

External resource for further context and technical grounding: https://www.aatcc.org/.

Final thoughts

Nylon totes have transcended their original function to become essential items in both fashion and practicality. Their robust construction, lightweight nature, and water resistance make them ideal for various uses, appealing to modern consumers and businesses alike. As we established throughout the chapter discussions, the journey of nylon from its historical roots to its current applications reveals valuable insights for business owners. Embracing high-quality nylon totes not only enhances brand reputation but also meets the increasing consumer demand for stylish yet durable solutions. Furthermore, considering environmental impacts related to nylon production can position businesses favorably in a marketplace that prioritizes sustainability alongside functionality.