Nylon tote bags have emerged as essential items in both the consumer market and among businesses seeking functional and stylish promotional products. Crafted to endure daily use, these bags provide notable durability and versatility that surpass many traditional materials. In exploring the benefits of nylon tote bags, we will first delve into their exceptional durability and material excellence, examining what makes them ideal for everyday business use. Following this, we will analyze their cost-effectiveness and the substantial value they offer to companies, making them a wise investment. Finally, we will highlight some of the latest design innovations in nylon tote bags that cater to modern design sensibilities while meeting practical needs. Together, these insights will illustrate how nylon tote bags can elevate your business’s appeal and functionality.

Strong Threads, Light Fabric: The Material Mastery Behind Durable Nylon Tote Bags

Durability in a nylon tote bag is not a single feature but a careful convergence of material science, weave architecture, and thoughtful construction. It is why a bag that weighs little in the hand can carry a heavy grocery load, shield contents from damp weather, and still look presentable after months of daily use. The appeal of nylon rests on a paradox: a synthetic fabric that can feel both featherlight and remarkably tenacious. The fiber chemistry gives nylon a natural resilience to abrasion and tearing, while the fabric engineering translates that resilience into real-world reliability. When you lift a well-made nylon tote, you sense that its strength is there long before a weight is placed inside. That balance between lightness and toughness is the result of choices that begin long before the yardage is cut and sewn. They start with the basics of denier, weave, and coating, and they extend through the stitches that bind the seams and the hardware that anchors the whole structure. The path from raw fiber to a durable tote is a story of layered decisions, each aimed at preserving function while minimizing upkeep.

At the heart of durability is nylon’s inherent resistance to water, abrasion, and mildew. Unlike natural fibers that drink in moisture and swell, nylon dries quickly and maintains its shape even when damp. This makes it well suited to grocery runs on rainy days, to travel where rain is a possibility, and to outdoor adventures where mud, dust, and light drizzle are common companions. The fabric’s performance improves dramatically when the right weave and finishing are paired with robust construction. The denier rating—an index of fiber thickness and, by extension, fabric weight—matters, but it is not the sole determinant of longevity. A 420D bag with a clever weave and durable stitching can outperform a poorly executed 1000D bag. The reverse is also true: heavy denier on a poorly designed tote can feel stiff, snag easily, and fail at stress points. So the modern nylon tote is a product of both material choice and craftsmanship.

Ripstop nylon represents a strategic design response to the everyday hazards a tote faces. The characteristic grid of thicker threads creates a built-in barrier to small tears, preventing damage from spreading across the fabric. This is not simply about defending against a pastry spill or a snag from a sharp edge; it is about preserving integrity under repeated use. In practical terms, ripstop weaves translate to bags that hold up under the jostle of commuting, the friction of corners brushing against doorframes, and the inevitable rubbing that comes with stuffing a bag under a chair or in a car trunk. Ballistic nylon, while rarer in everyday totes, embodies a higher rank of toughness. Its dense weave and tightly packed fibers resist scuffing and tearing and bring a sense of military-grade durability to the design even when the bag is carried for hours or loaded with substantial weight. While ballistic nylon can be stiffer, when used with a thoughtful layout it delivers long-term resilience without sacrificing everyday convenience.

Beyond the weave, the fabric’s surface finish plays a decisive role in performance. A polyurethane or silicone coating can transform a bag’s water resistance and abrasion resistance, offering a degree of environmental durability that raw nylon cannot achieve on its own. A coating creates a water-repellent barrier that helps keep contents dry during sudden showers and damp storage. It also adds a degree of tear strength by reducing fiber movement at the surface where stresses concentrate. The layer that protects the interior from moisture matters as much as the outer face. In practice, durable nylon totes often rely on a dual strategy: a high-density weave for mechanical strength, paired with a coating that raises water resistance without making the fabric too stiff or too heavy.

Construction quality is where the theory meets daily use. A well-made nylon tote uses double or even triple stitching at every stress point—especially where handles join the body, where corners meet, and along any seam that bears weight. The stitching plan matters as much as the thread itself. Bonded nylon thread offers resilience against fraying and UV exposure, ensuring seams hold together when the bag is pressed to its limit. Reinforced hardware completes the package: metal grommets, sturdy carry handles, and reliable, smoothly operating closures. The objective is straightforward: when the bag is loaded, the seams should not be the first place users notice wear. The difference between a bag that lasts a year and one that endures for five lies in those detailed choices—where the thread count, stitch type, and seam geometry work in concert to distribute stress and minimize fatigue.

The science of material selection and the art of construction come together in a simple, honest verdict: durability improves most when each layer supports the others. A practical nylon tote balances weight and resilience. A lighter 420D or 600D fabric reduces fatigue on the shoulder and lowers energy cost in daily handling, yet when paired with a robust weave, a strong interior lining, and fine-tuned stitching, it becomes remarkably durable. The trend toward lighter yet sturdier fabrics mirrors a broader shift in how people use bags today. These totes are not merely containers but reliable partners for daily routines that stretch across work, groceries, travel, and weekend getaways. The goal is straightforward—deliver a bag that can carry what you need, stay comfortable in hand or on the shoulder, and recover quickly from the inevitable bend, drop, and spill.

In practice, many durable nylon totes blend a thoughtful fabric with interior organization that protects both contents and the bag itself. Inner zipper pockets, padded or reinforced handles, and hidden seams reduce abrasion and keep high-use regions from showing signs of wear early. Interior pockets provide structure, preventing the interior from collapsing into a sagging mass when loaded; they also concentrate weight toward the bag’s center of gravity, reducing strain on the handles. The design philosophy favors simplicity and reliability over flash and novelty. A bag that delivers long-term value is easier to maintain, easier to clean, and easier to repair. It is not merely about resisting the worst weather; it is about staying functional after the routine, day-in, day-out tasks that define modern living.

Cleaning and maintenance are often overlooked as a durability determinant. Nylon’s smooth surface resists stubborn stains and cleans up with a quick wipe. The coating layer, if present, will require occasional care to maintain its hydrophobic properties. Gentle cleaning avoids harsh chemicals that can degrade coatings and fibers over time. A damp cloth is usually sufficient, followed by air drying away from direct heat. The aim is not to shine a street-ready surface but to preserve the bag’s original texture and color without compromising the fabric’s integrity. Regular maintenance helps keep the tote looking fresh while preserving the structural elements that support everyday use.

Durability is also about long-term value, which is often assessed through the lens of cost-per-use. A nylon tote that lasts multiple years with minimal maintenance can justify a higher upfront cost when spread across many uses. Conversely, a cheaper, poorly constructed model may accumulate wear quickly, leading to more frequent replacements and higher cumulative costs. The assessment hinges on a practical math of use frequency, load expectations, and the number of seasons endured. It is a reminder that the most cost-effective choice is the one that fails least often and requires the least upkeep.

In this space, the conversation about durability naturally extends to a broader question: how should a consumer interpret denier and weave when evaluating a bag? The answer is nuanced. Denier matters because it reflects potential load-bearing capacity and abrasion resistance, yet the fabric’s ultimate performance depends on weave quality and finish. A specialized grid-like construction, the ripstop, is designed to arrest the spread of damage, a feature that becomes especially valuable when a bag faces rough corners, zipper rubs, or the occasional snag from a rough edge. Ballistic variants set a higher bar for scuff resistance and tear resilience, often paired with coatings that improve water resistance and surface protection. But even these high-performance fabrics must be married to careful stitching and strong hardware to reach their full potential. The lesson is clear: durability is a system attribute, not a single specification. The denier, the weave, the coating, the stitching, and the hardware each contribute to a final product that can weather the rhythm of daily life.

From a design standpoint, this means prioritizing features that improve longevity without adding unnecessary weight. Internal pockets and gussets can stabilize contents and spread load, reducing the chance of stress concentrations on the seams. Pad points on handles and reinforced attachment points further minimize wear. The hardware should be purpose-built for repeated use, with smooth operation and secure closures that resist jamming or snagging. In an era when bags are expected to perform across multipurpose roles—from commuting to weekend markets to light travel—the durability narrative has evolved from simple ruggedness to adaptive resilience. A bag that can be folded for compact storage, quickly wiped clean, and brought back into service after a rain shower demonstrates a thoughtful alignment between material properties and user needs.

Consumers who are curious about the mechanics behind these claims can explore practical guides that synthesize material science with field testing. A well-rounded durability evaluation weighs real-world performance data, the science of fiber and weave, and the quality of construction in ways that transcend glossy marketing. This approach empowers buyers to move beyond weight alone and toward a holistic understanding of which nylon totes truly stand the test of time. For those who want to dive deeper into hands-on factors like zippers, pockets, and reinforced corners, a concise resource covers these design details and demonstrates how they contribute to longevity in everyday use. See the guide on tote bags with zippers for a focused look at hardware reliability and interior organization that supports durability.

In sum, the durability and material excellence of nylon tote bags emerge from a disciplined orchestration of fabric selection, weave strategy, surface finishing, and robust construction. The result is a category of carryalls that feels light yet sturdy, flexible yet dependable, and stylish yet practical. This synthesis is the reason nylon totes have moved from utilitarian corners to mainstream daily life, where a single bag can shoulder groceries, commute essentials, and a weekend’s worth of gear without faltering. It is a testament to how modern materials science, when paired with thoughtful craftsmanship, can transform a simple tote into a durable companion for the long haul. For a broader, data-driven examination of durability factors, readers may consult external resources that compile performance data and empirical testing across a range of nylon constructions: https://www.outdoorgearlab.com/nylon-tote-bag-durability-guide

Durable and Dollar-Smart: The Real-World Value of Nylon Tote Bags

Nylon tote bags reveal their true value when daily life tests the math of cost and convenience. The question is not only what a bag costs at purchase, but what it costs over time as it carries groceries, books, laptops, and gear across seasons. Durability translates into fewer replacements, less waste, and a lower per-use price that surprises shoppers who expect savings only from the sticker price. The value here extends beyond the ledger, shaping how people move through crowded streets and adapt a single accessory to many roles.

Beyond the initial price, cost-per-use clarifies nylon totes’ advantages over less durable materials. A well-constructed nylon tote resists abrasion, moisture, and daily wear. It can be wiped clean, dries quickly, and stores compactly when not in use. Maintenance ease compounds utility, turning a purchase into a long-term companion. In contrast, bags made from pilling, shrinking fabrics or poor stitching wear out sooner and require more frequent replacements.

The material science matters: ballistic nylon and ripstop variants offer high strength and tear resistance, while coatings improve water resistance without sacrificing flexibility. Reinforced handles and secure closures further extend life, reducing the need for early retirement and protecting the bag’s function over years.

For consumers, mid-denier options (e.g., 420D–600D) balance weight, price, and durability. Such bags feel light yet sturdy, accommodate everyday loads, and maintain shape with proper care. Well-designed interiors, comfortable handles, and understated branding help a nylon tote transition from commute to weekend use without looking worn.

Sustainability adds to value when recycled nylon is used. Recycled nylon reduces virgin polymer demand while preserving strength and abrasion resistance. The lower environmental footprint, combined with long life, aligns with consumers who want practical performance and responsible choices.

Maintenance is straightforward: a quick wipe removes surface dirt, air-drying restores feel, and routine cleaning keeps fibers strong. The material’s moisture resistance helps prevent mildew, enabling reliable use across climates and seasons. In this way, nylon totes offer a predictable cost pathway with fewer surprise expenses tied to care or replacement.

To compare with alternatives, consider leather’s durability and care needs. Leather may last long but requires conditioning and suffers higher upfront costs and resale variability. Nylon often delivers years of service at a fraction of leather’s price, especially when recycled content is part of the design.

Overall, the long-term value of a nylon tote lies in reliability, adaptability, and simple maintenance. It remains a practical choice for students, professionals, travelers, and daily commuters who want a versatile bag that can endure, be reused, and stay useful across years.

Carrying the Future: Design Innovations that Elevate Nylon Tote Bags from Utility to Everyday Icon

Nylon tote bags have moved well beyond their utilitarian roots, evolving into a canvas for engineering, fashion, and everyday problem-solving. What starts as a practical accessory capable of carrying groceries or a laptop has become a thoughtfully engineered system that prioritizes comfort, protection, and personality. Designers who work with nylon tote bags understand that the true measure of a tote is not just how much it can hold, but how gracefully it carries the load, adapts to shifting contexts, and ages with dignity. The chapter that follows traces how advancements in materials, construction, and intelligent features coalesce into bags that feel reliable, modern, and almost effortless to live with. The result is a class of carryalls that can be used across a spectrum of moments, from a daily commute to a weekend adventure, while also serving as a quiet expression of taste and responsibility. The journey begins with materials, moves through structure, and culminates in how form and function meet real-world use in ways that redefine what a tote can be.

At the heart of these innovations lies a refined choice of materials. Nylon, by its nature, blends lightness with impressive strength, but the real leap comes when engineers select grades that push performance beyond the bare minimum. Ballistic nylon, with variants typically ranging from 1050D to 1680D, offers a level of abrasion resistance and puncture tolerance that is especially valuable in commuter and travel totes. This material, born of military applications, is prized not only for its tough exterior but for the way it wears gracefully over time. Ripstop nylon adds another layer of resilience through its distinctive crosshatched weave. The design intention here is simple but powerful: a small tear should not mushroom into a larger fault. This weave, when paired with appropriate coatings, creates a fabric that can withstand rough surfaces, seat belt friction, and the daily rattle of an active life. The use of these fabrics reflects a broader philosophy in modern tote design: durability is a baseline, not an afterthought, and longevity is a feature that compounds value over time.

Coatings have become a pivotal aspect of performance without compromising aesthetics. A polyurethane (PU) or silicone coating can dramatically improve water resistance and tear strength, extending a tote’s range of usable environments. The coating acts as a barrier against moisture and abrasion, allowing a bag to thrive in rain, on damp commutes, or during quick trips through wet environments. Coatings also influence the bag’s tactile feel and weight distribution, subtly shaping the user’s perception of quality. But coatings are not a one-size-fits-all solution; designers select them with an eye toward balance. Too heavy or rigid a coating can alter drape and flexibility; the art lies in choosing a coating that preserves the fabric’s suppleness while enhancing performance where it matters most. In this sense, material choice becomes a negotiation between lightness, resilience, and the sensorial experience of handling the bag.

Structural design has evolved in parallel with material science to optimize how a tote carries its load. Reinforced bar-tacked straps and double or triple stitching at high-stress points translate fabric strength into durable performance. The handle attachments, corners, and base areas are typically the first to show wear in everyday use; thus, focusing reinforcement in these zones is a practical practice that pays dividends over years of use. Ergonomics have also moved forward. Modern nylon totes often feature padded or adjustable shoulder straps that distribute weight more evenly across the body, reducing fatigue during longer carries or when the bag is loaded with heavier items like laptops, gym gear, or groceries. The logic is straightforward: if the strap system is comfortable, users are more likely to rely on the tote in varied circumstances, which in turn reinforces the bag’s role as a daily companion rather than a seasonal accessory.

Inside, functional linings and organizational features transform a simple bag into a portable micro-environment. Thermal linings illustrate how a tote can do more than hold items; they can help maintain temperature for specific contents, a feature that becomes especially valuable for travelers or those who transport perishable items. The modern tote also embraces interior zippered compartments and hidden pockets that contribute to security and order. RFID-blocking pockets may not be standard on every model, but the idea of protecting sensitive data when carrying a wallet or devices resonates with a broad audience. The lining choices, including reinforced seams and moisture barriers, are not cosmetic details but elements that preserve the integrity of the bag’s interior over time. These features reflect a broader shift toward thoughtful interior planning, where the goal is not simply to maximize capacity but to maximize the ease and efficiency of use.

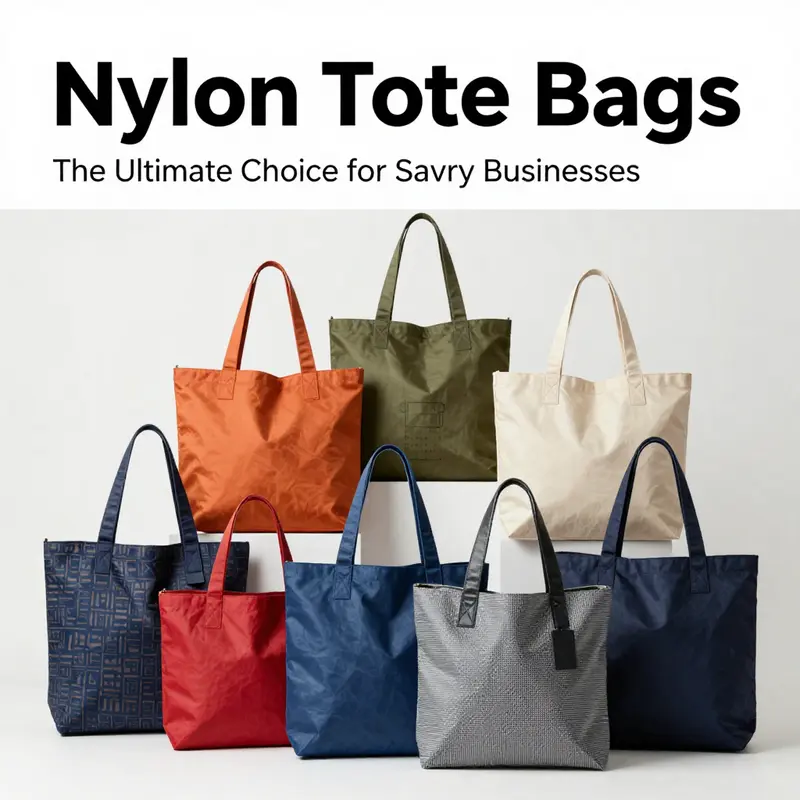

Aesthetic versatility is another pillar of contemporary nylon tote design. Colorfast dyes ensure that hues stay vibrant after repeated washes, exposure to sunlight, and general handling. The availability of bold color options invites users to express personal style or to coordinate with outfits and professional settings. Beyond color, modular design elements enable a degree of customization that resonates with consumers seeking a sense of control over their accessories. Zippers, hardware, and fabric panels may be chosen to create a cohesive look that feels polished in a corporate setting or playful in a casual one. The trend toward cohesive hardware—where zippers, buckles, and pulls are harmonized in tone and finish—creates a visually integrated piece that looks as good in an office corridor as it does on a street corner. In this fashion-forward approach, a nylon tote becomes less a disposable good and more a durable instrument of daily life that carries personal meaning as well as belongings.

The core insight many designers emphasize is that thickness or weight alone does not determine resilience. A well-made lightweight bag can outperform a heavier bag that has been poorly stitched. This principle challenges a common assumption: that more material automatically equals more durability. Instead, craftsmanship—precise stitching, balanced load distribution, and thoughtful assembly—supersedes simple density. A 420D bag, for instance, can outlast a fatter model if the seams, bar-tacks, and panel interfaces are engineered with care. This nuance matters because it reframes how consumers evaluate value. Rather than chasing the heaviest option, they can look for print-ready signals of construction quality—bar-tacked straps, reinforced corners, and a fabric that stays taut and smooth even when loaded. The result is a tote that feels sturdy yet remains surprisingly nimble in daily tasks.

Sustainability threads through these design decisions as well. Recycled and high-density nylon variants are increasingly common, reflecting a broader shift in the fashion and textiles industry toward circularity and responsible sourcing. When a bag is designed to endure, it also reduces waste. The conversation around sustainability is not solely about the material’s origin; it is about the full lifecycle—the way a product is built, how it ages, and whether it can be repaired or repurposed when its moment of usefulness wanes. Nylon’s durability becomes a contributor to a more sustainable practice when paired with repair-friendly constructions, accessible maintenance, and the possibility of upgrading components like straps or linings instead of discarding the entire bag. In this sense, a well-designed nylon tote is not just a carrier of goods but a statement about long-term thinking and craft that respects resources.

In practical terms, the modern nylon tote dissolves the line between function and identity. It suits a range of contexts—from a train seat to a conference hall, from a weekend market to an airport lounge. The latest iterations emphasize adaptive interiors: flexible panels that can be reconfigured to accommodate a laptop sleeve, a water bottle, or a compact change of clothes; detachable pouches that can be placed in a car glove compartment or zipped to a main pocket; thermal sections that keep snacks fresh without requiring a separate bag. Features like interior organizers or modular add-ons invite a tactile flexibility, enabling users to tailor the bag to a specific day’s plan without sacrificing aesthetics or comfort. The design dialogue thus becomes a negotiation between adaptability and restraint, ensuring the tote remains a versatile companion rather than a collection of possible, unused features.

From the perspective of a consumer, the cost-benefit calculus of a nylon tote hinges on a simple but powerful metric: cost per use. A tote that costs more upfront but endures for years often delivers a lower per-use cost than a cheaper bag that fails after weeks. This approach shifts the focus from a price tag to a lifecycle performance narrative. It aligns with a growing consumer interest in quality over quantity and in products that combine utility with responsible production practices. As a result, the nylon tote marketplace has seen a flourishing of options that emphasize durability, repairability, and timeless design over disposable novelty. This shift makes a bag an investment that pays dividends in reliability and flexibility across seasons and contexts.

In design conversations, the user experience remains central. The bag must feel intuitive to use: accessible pockets, clear orientation of compartments, comfortable handling, and a sense of balance when carried. The ergonomics of load distribution matter as much in daily errands as in longer journeys. For those who travel, a well-organized interior can reduce the stress of navigating busy terminals, while the exterior can provide quiet resilience against the occasional knock or snag. The interplay between exterior resilience and interior order is a hallmark of contemporary nylon tote design, signaling a maturity in which form follows function without surrendering style.

As with any evolving product category, there is value in looking beyond aesthetics to understand how these design choices translate into everyday benefits. A high-quality nylon tote can reduce the number of bags a person needs to own by offering a blend of durability, style, and versatility. It can function as a reliable grocery carrier one day and as a sleek carry-on for a short trip the next. The adaptability of materials and construction means that a single tote can be used across multiple lifecycles, from daily routines to seasonal adventures, without demanding a replacement for every new need. The result is not simply a bag but a reliable partner that keeps pace with an active life, learning from each use and responding to new requirements with thoughtful design choices.

To appreciate the design language of these bags, consider how a single feature set can influence everyday decisions. The reinforced straps translate into less concern while commuting on crowded transit or steering through a bustling market. The thermal linings and internal pockets translate into fewer items wandering through life, because belongings have a designated home with a predictable logic. The choice of dyes and hardware translates into a bag that fits a formal setting or a casual outing with equal ease, minimizing the cognitive load of dressing or packing. The result is a carry mode that feels natural—an extension of the wearer rather than an obstacle to daily movement.

In this sense, design innovations in nylon tote bags are proof that engineering and aesthetics can move in tandem. The best designs acknowledge that users do not want to choose between practicality and personality; they want both. The modern nylon tote speaks to someone who values efficiency, durability, and personal expression in equal measure. The narrative of these bags is a continuous dialogue between materials science and human behavior, where each improvement in weave, seam, or pocket arrangement translates into a smoother daily rhythm. The tote becomes a trusted partner in the small rituals of life—a way to carry hopes, plans, and essentials with confidence and ease.

For readers who want to explore the practical implications of these developments further, a closer look at how features translate into real-world use can be enlightening. The design choices described here are not merely about showcasing a material’s prowess; they are about shaping everyday routines. The interplay of durable fabrics, thoughtful interiors, ergonomic support systems, and adaptable aesthetics creates a product that can hold up under the pressures of modern living while still feeling effortless to carry. In this way, nylon tote bags reflect a broader trend in product design: prioritizing intelligent systems that enhance life, not just add to it. The result is an accessory that remains relevant as days grow busier and demands evolve, proving that a well-made tote can be both a workhorse and a style staple.

As the chapter closes, it is worth noting how these design principles translate into the market’s wider conversation. Consumers increasingly expect products to perform across contexts, to endure, and to be repairable rather than disposable. In response, designers are refining not only materials and constructions but also the pathways for care, maintenance, and potential upgrades. The promise of these innovations lies not only in better bags but in a shift toward a more thoughtful relationship with everyday objects. The nylon tote, once a simple carrier, now embodies a philosophy of durable, adaptable design that aligns with contemporary life’s demands while inviting personal expression through color, texture, and modular features.

For readers who want a concrete glimpse into how these ideas translate into practice, consider the ongoing emphasis on secure, organized interiors and modular customization. The trend toward zipped compartments, detachable organizers, and compatible accessories demonstrates a future in which a tote is less about one fixed configuration and more about a flexible toolkit for everyday planning. This adaptability resonates with professionals who switch between meetings and errands, travelers who need compartments for tech and travel documents, and casual users who value a bag that looks good while carrying the essentials with ease. The synthesis of advanced materials, reinforced construction, and interior intelligence marks a new epoch for nylon tote bags—an epoch that treats the bag not merely as a carry vessel but as a thoughtfully designed extension of the wearer’s daily life. And in this evolving landscape, the best designs remain quiet in their confidence, offering stability, convenience, and style without flamboyance, proving that true innovation often speaks softly but deeply through everyday usefulness.

To those who are curious about how these concepts translate into real world examples, a practical takeaway is to look for bags that balance weight, durability, and finish while offering interior organization and ergonomic support. The presence of reinforced straps, density-appropriate fabrics, and well-sewn seams signals that a bag is built to last. The choice of color and hardware should align with the user’s aesthetic and the bag’s intended environment. In the end, design innovations in nylon tote bags converge on one simple truth: durability plus usability plus personal expression creates a carry that is not merely worn but lived in. The tote becomes a faithful partner, ready to accompany a busy schedule, adapt to shifting needs, and carry countless small moments of everyday life with quiet resilience. For those who care about both performance and appearance, this is the frontier where functionality and fashion meet—and where the humble tote bag proves to be a remarkably sophisticated instrument for modern living.

For further exploration of material integrity and construction standards that undergird these innovations, see the external resource that provides a deeper technical perspective on nylon tote bag materials and performance: https://www.sustainablefashionforum.com/guides/nylon-tote-bag-material-integrity. And for readers seeking additional context within this site, an example of related practical content can be found at tote bags with zippers.

Final thoughts

In conclusion, nylon tote bags represent a perfect marriage of durability, cost-effectiveness, and contemporary design that businesses can leverage. Their exceptional material properties ensure longevity, making them not just functional but also a sustainable choice for promotional purposes. By understanding the features and benefits discussed, business owners can confidently select nylon tote bags as an integral part of their marketing and operational strategies. Modern consumers seek quality, and high-performing nylon totes meet these expectations while enhancing brand visibility and customer experience.